Chainsaw chains come in all sorts of shapes and sizes – there are so many different combinations it’s sometimes impossible to know where to start. In this article, we’ll take a look at the three core dimensions of a chainsaw chain, and then discuss the pros and cons of various different types of chain.

The three key things you need to consider when looking at a chainsaw chain are pitch, gauge, and chain length. Let’s take a look at these in more detail. All are key to understand before you reach for your chainsaw sharpener.

Chain Pitch

Chain pitch is used to describe the length between two links in the chain. It is defined as the distance between two drive links, divided by two. A drive link is the link protruding from the inside of the chain. You can tell the inside of the chain because all the protrusions are identical, and shaped like shark’s teeth.

There are 4 main chain pitches – ¼”, .325”, 3/8” and .404”. Selecting the correct pitch chain ensures your chain meshes properly with the sprocket on the chainsaw, and the chain doesn’t skip on the sprocket. Pitches aren’t interchangeable: if you use a 3/8” saw (by far the most common), you have to use a 3/8” pitch chain.

Chain Gauge

A chainsaw chain’s gauge describes the width of the drive teeth on the chain. This is determined mainly by the width of the notch in the chainsaw bar. There are 4 common chainsaw chain gauges: .043”, .050”, .058” and .063”.

Like chain pitch, chain gauge is defined by your chainsaw, and you cannot use chains that are not the correct gauge for the saw. Like the chain pitch, this is often written on your chainsaw so you can find the correct match.

Chain Length

Obvious, but nonetheless important – the length of the chainsaw chain. This is defined by the length of the bar on your chainsaw, and is measured in drive links. Too short a chain and it won’t fit on the saw, too long and you won’t be able to tension it correctly.

3/8” Standard vs. 3/8” Low Profile

There is one final dimension to consider – and it is specific to the 3/8” size chain. That is Standard Profile vs Low Profile. These two are not interchangeable, and describe the height of the link. Standard profile is a taller link, while low profile is – you guessed it – a shorter link. Both are common, and you’ll need to check to determine which is the correct type for your chainsaw.

Different Types Of Chainsaw Chain

Now we have covered the main dimensions of the chainsaw chain, you can make sure it fits your saw. But that is only half the puzzle – as there are many different types of chainsaw chain, all with different characteristics. We can’t cover them all, but we’ll discuss some of the most common.

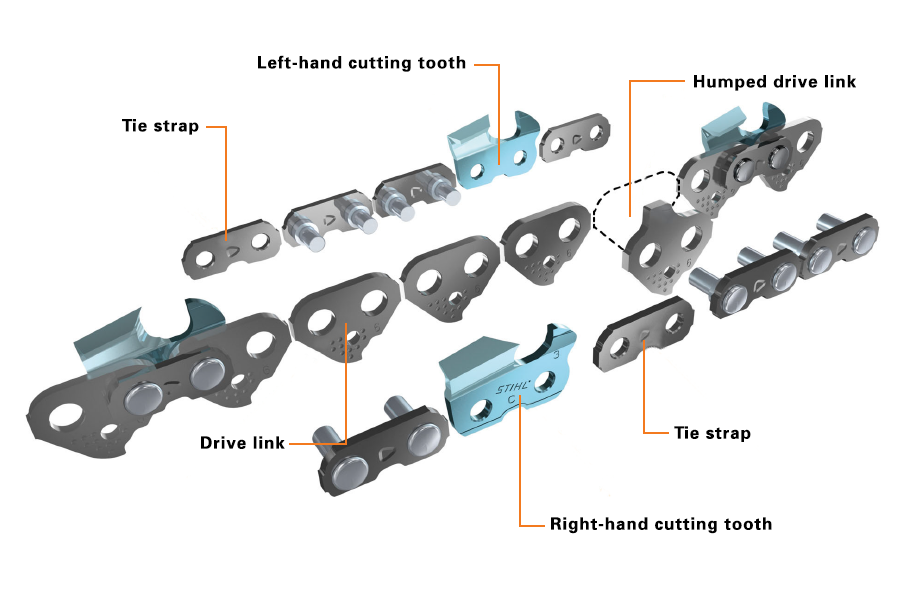

First, let’s quickly discuss the anatomy of the chainsaw chain to enable us to discuss the differences in different types. The image below helps explain the terminology for the different parts of the chainsaw chain.

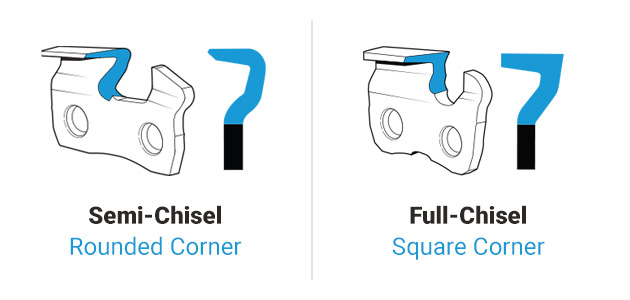

Full Chisel vs. Semi Chisel Chains

Full chisel chains have a very slightly different profile when compared to semi chisel chains. Looking from the front, you can see that the top plate corner has a square edge on a full chisel blade, and a rounded corner on a semi chisel blade.

Semi chisel blades are most common, and are the most versatile. These work well in a range of cutting conditions – including hard or soft wood and the presence of dirt. Full chisel chains cut much more efficiently, but they also dull much quicker. Typically, they are best reserved for soft, clean, fresh wood.

Round Ground vs. Square Ground

Round ground chains have a rounded profile when you look at the cutting tooth from the side. These are easily the most common on consumer chainsaws because they are so versatile.

Very occasionally, you might see a square ground chain. Like full chisel chains, these also cut more efficiently than round ground chains, but they are harder to sharpen accurately, and they dull faster as well.

Generally, we recommend sticking with your round ground chain unless you have a good reason to change it.

Standard Chains vs. Safety Chains

Safety chains are a new innovation that attempts to reduce kickback. This is achieved by adding another link near the depth gauge. As the chain moves around the tip of the saw, this extra raised link attempts to bounce off obstructions rather than ricocheting like a normal chainsaw chain. The result is to decrease kickback.

Standard, Semi Skip & Full Skip

You will occasionally read about full skip chains, semi skip chains and regular chains. Standard chains are the most common, and are what you find on most consumer chainsaws. Semi skip chains differ in that they leave more space between the cutting links, and full skip chains leave even more space.

This design is intended for large powerful chainsaws, to enable more space for wood chips to be ejected from the saw blade. They aren’t that common, and don’t really make sense unless you are using a very large type of chainsaw – like a rancher chainsaw.